Jinan T packing machinery co.,ltd

Jinan Eagle nuts and snacks automatic filling, capping and label machine for jars and cans type packing

I. Model configuration

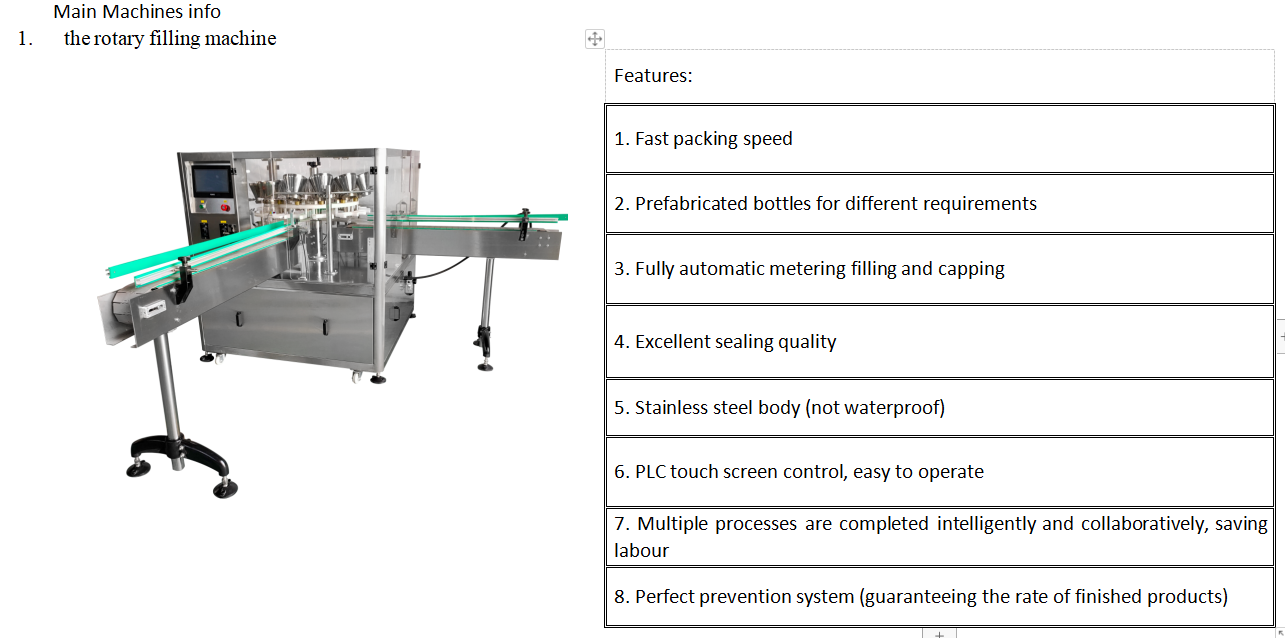

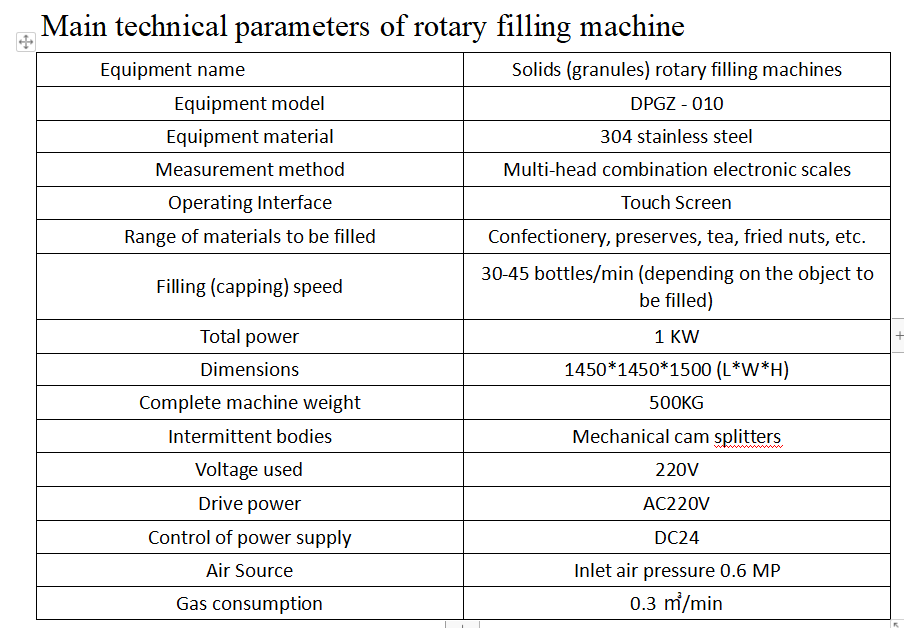

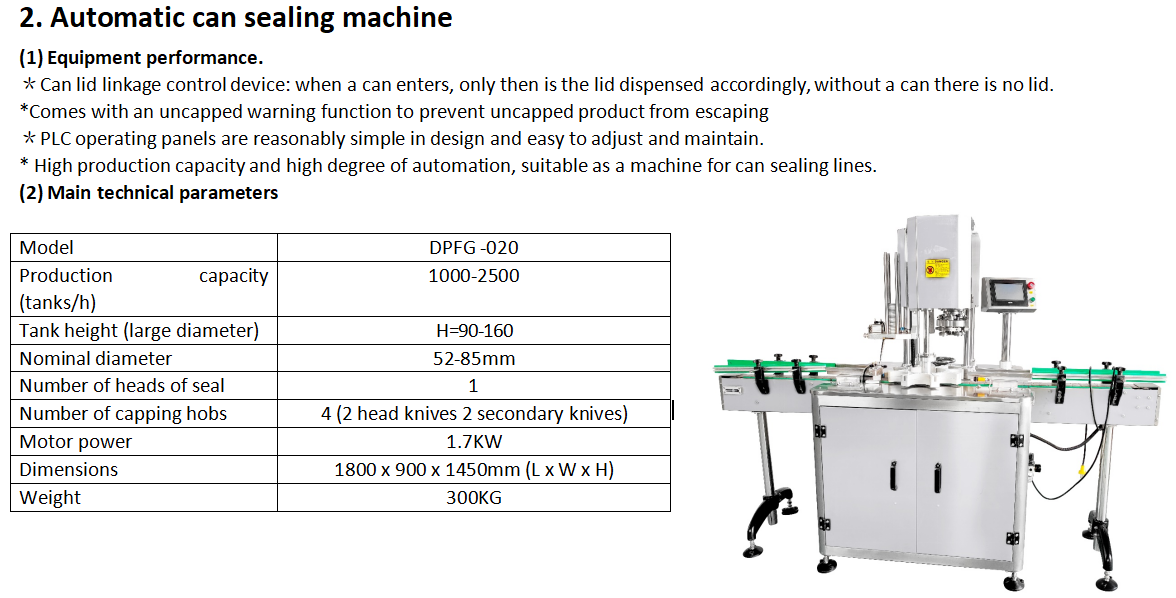

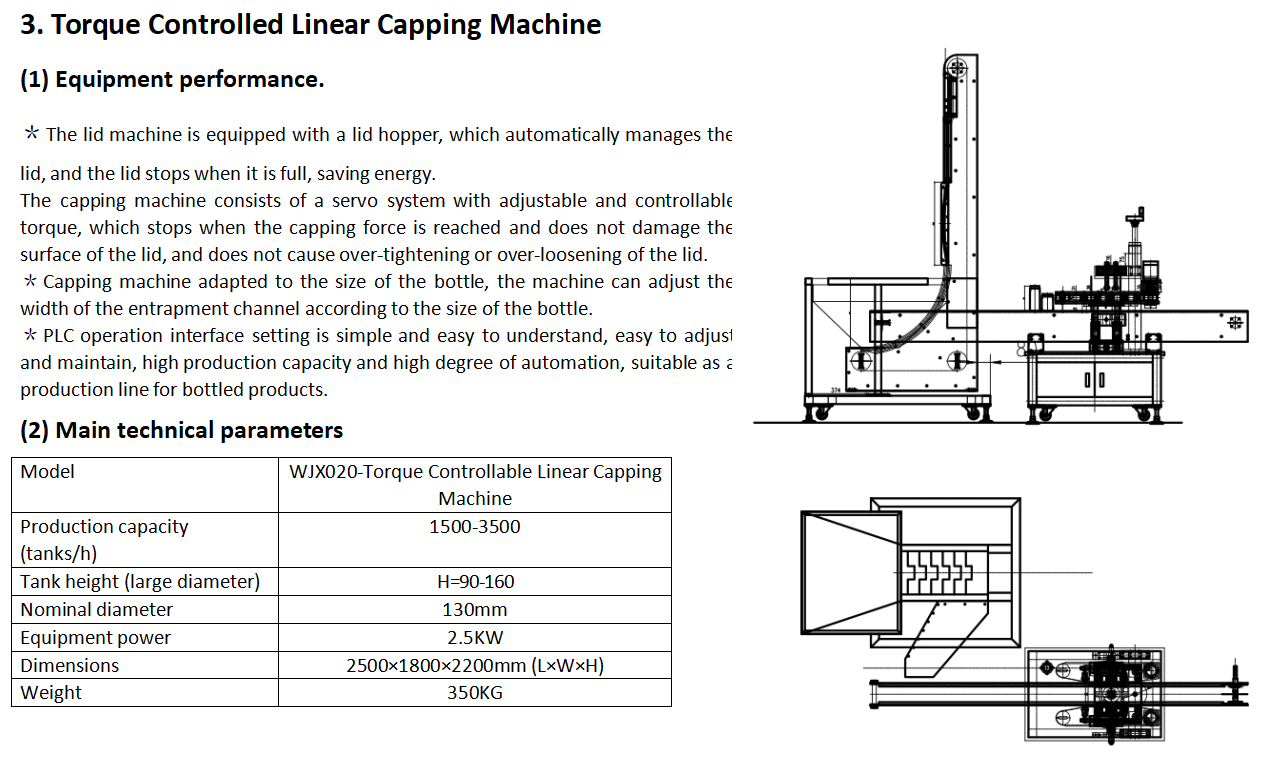

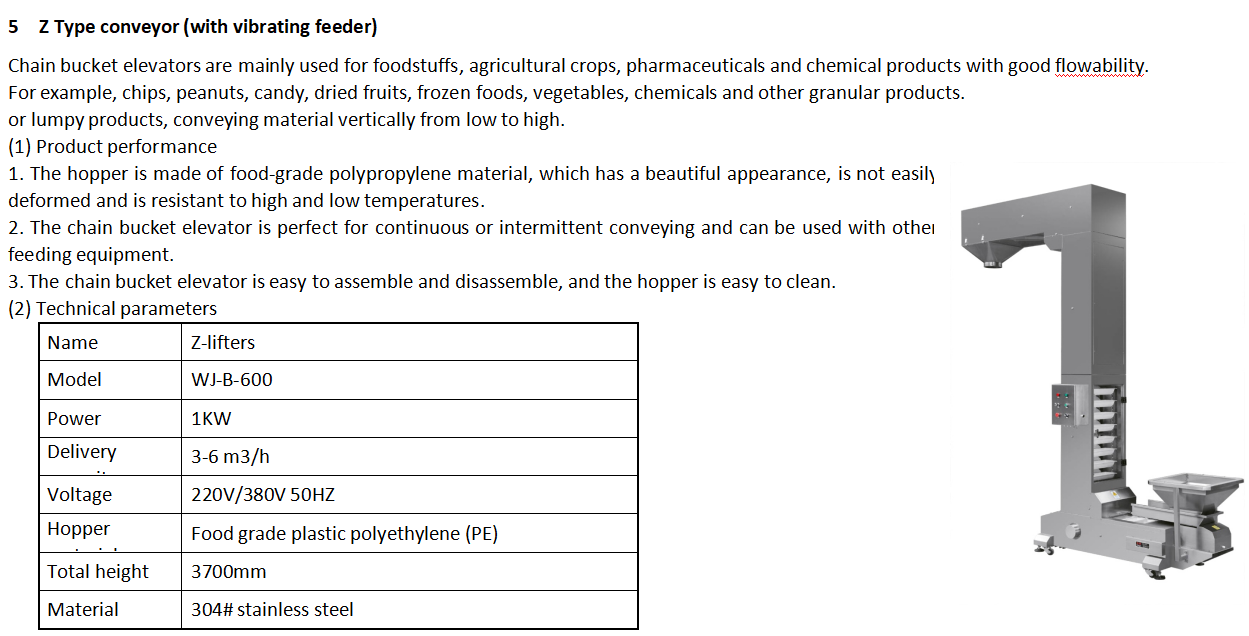

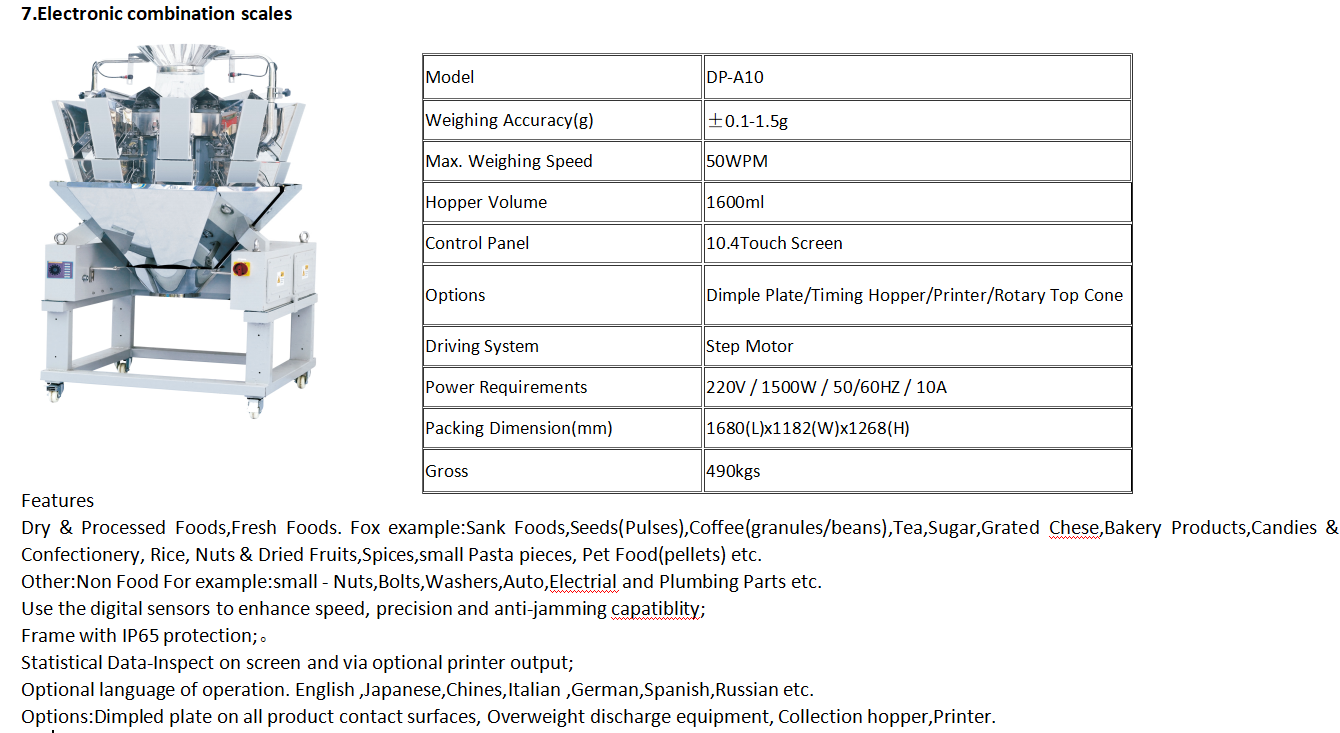

Rotary filling machine + Z-loader + 10-head combination weigher and working platform + automatic can sealing machine + automatic capping and capping machine + double side labelling machine

II. Advantages.

1、Improve production efficiency and reduce costs

2、Improve product quality and upgrade products

3. Improve hygiene standards

4. Save 12-17 people

III. Description of the product packaging workflow.

Manual bottle discharge to conveyor belt - Empty bottle transfer - Rotary filling machine - Combined weighing and discharging - Material filling - Automatic can sealing machine - Automatic capping machine - Automatic capping machine - Automatic capping machine - Automatic labelling.

Description of the workflow and characteristics of the filling line

1. Manual bottle discharge to bottle feeding conveyor. (Equipped with no bottle alarm device)

2. Bottle detection by photoelectric system. (Reaching no bottles to stop discharging)

3. Material to the bottle above the hopper anti-blocking device began to vibrate to achieve a balanced underfeed, to prevent the material bonding blockage of the underfeed port.

4. After the filling material has reached the bottle, it is brought to the can sealing machine via the conveyor belt to complete the aluminium cap sealing.

5. The finished product goes into the capping area

6. The capping machine automatically puts on the lid and the capping machine completes the capping work.

7. Automatic labelling by labelling machine.

8. Finished product.