Jinan T packing machinery co.,ltd

Jinan Eagle doypack packaging machine for nuts and snack food chips, pet dog food, dental chews

Key words: dog food doypack packing machine, nuts packing machine

1、It Apply to blocks, plates, strips, granular material such as: candy, peanuts, green beans, pistachios, sugar, seeds, nuts, candied fruit, puffed food, soy products and so on.

2、It is characterized by mechanical replace human packaging, product packaging enterprise automation, improve productivity and dramatically reduce product cost. It can effectively reduce the material aspects of the pollution in the packaging, finished sealing quality and aesthetics good, suitable for high-volume automated enterprise product packaging.

Jinan T packing servo type doypack packaging machine

Given bags Production Line Uses and Features

1、It Apply to blocks, plates, strips, granular material such as: candy, peanuts, green beans, pistachios, sugar, seeds, nuts, candied fruit, puffed food, soy products and so on.

2、It is characterized by mechanical replace human packaging, product packaging enterprise automation, improve productivity and dramatically reduce product cost. It can effectively reduce the material aspects of the pollution in the packaging, finished sealing quality and aesthetics good, suitable for high-volume automated enterprise product packaging.

Equipment specifications and performance

3.1 GDS210-10 automatic bag filling and packaging machine

GDS210-10 Main features:

1. PLC, HMI control system, touch screen operation is simple and intuitive.

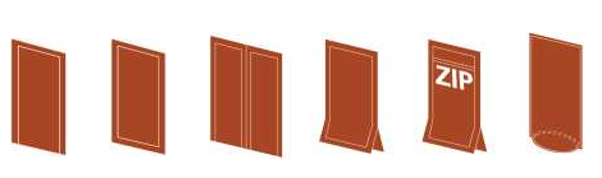

2. Applicable to a wide range of packaging bags, the multilayer composite film, single PE, PP, etc. made of pre-made bags, paper can be applied. Finished bag pattern perfect sealing quality, high grade.

3. Smart thermostats, temperature control accuracy, ensure nice, smooth seal. 4. Perfect automatic alarm protection, the losses to a minimum. 5. Local and metering equipments, automatic feeding, measuring, filling, date printing the entire packaging process,

6. Main motor with frequency control, production, according to actual needs on the color touch screen in a certain range of frequencies arbitrarily set.

Technical parameters | |

type | GDS210-10 |

Mechanical station | Ten stations , all servo controlled |

Bag Type | Flat bags, pouches, four sides sealed bags, side seal bags composite bag, with or without zip type bags |

Bag Size | Width:90*210mm Length: within360mm |

Packing speed | ≤82Bags / min(The speed depends on the material itself and the fill weight ) |

Machine weight | 1000Kg |

Voltage | 380V Three-phase 50HZ/60HZ |

Total power | 2.5KW |

Compressed air consumption | 6kg/cm² 0.4m³/min(Provided by the user) |

Dimensions | 1950(L)* 1400(W)* 1520(H)mm |

Model to choose according to the bag size

| Model | Station | Speed | Bag size mm | |

| GDS210-10 | 10 | 0-100 | bags/min | Width:80-210 Length:120-380 |

| GDS260-08 | 8 | 0-72 | bags/min | Width:130-260 Length:400≤ |

| GDS300-08 | 8 | 0-65 | bags/min | Width:160-300 Length:400≤ |

| GDS210-08H | 10 | 0-50 | bags/min | Width:80-210 Length:120-380 |

| GDS210-06 | 6 | 0-60 | bags/min | Width:80-210 Length:120-380 |

| GDS260-08F | 8 | 0-72 | bags/min | Width:130-260 Length:400≤ |

| 2 in 1 Whole body machine (GDS100A-2) | 10/2 | 0-65 | bags/min | Width:80-210 Length:120-380 |

| GDS300-08G | 8 | 0-40 | bags/min | Width:160-300 Length:600≤ |

| GDS350-08G | 8 | 0-30 | bags/min | Width:250-350 Length:600≤ |

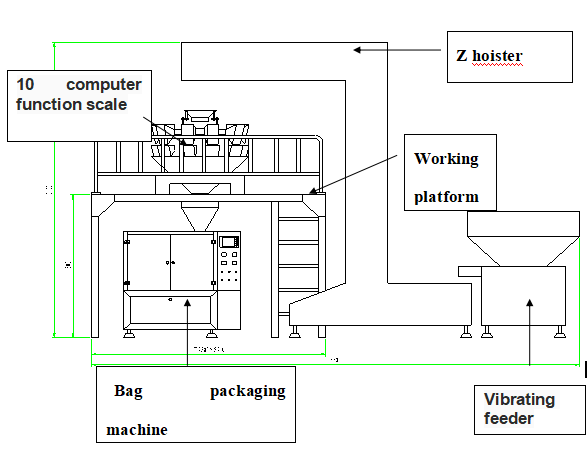

4. Z type bucket elevator and turn Feeder

Z type bucket elevator and turn Feeder

Product Description: 4.1, Z-type transfer material hoist bucket Z-turn by the bucket elevator (Ⅰ Generation) and feeder composition. With the weigher and bag packaging machine to constitute quantitative automatic packaging system, widely used in food, feed and chemical packaging industry.

1.2, Z-type transfer bucket elevator (Ⅰ Generation) driven by a chain drive hopper elevators for vertical transportation of bulk materials and small particles, improve, and enhance the advantages of high. Mainly made of stainless steel and food grade plastic polypropylene made of PP, safety and health. By the control circuit and the material level detection for automatic feeding and stop automation.

43, using electromagnetic vibration feeder principle for power, with a stable, high-speed, throughput, and almost zero noise. Mainly from stainless steel, safety and health. By the control circuit and the material level detection for automatic feeding and stop automation.